KEV QHIA TXOG

| Lub Npe Khoom | Xov flange |

| Loj | 1/2"-24" |

| Siab | 150 # - 2500 #, PN0.6-PN400, 5K-40K |

| Tus Qauv | ANSI B16.5, EN1092-1, JIS B2220 thiab lwm yam. |

| Hom xov | NPT, BSP |

| Khoom siv | Cov hlau tsis xeb:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo thiab lwm yam. |

| Cov hlau carbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 thiab lwm yam. | |

| Ob chav stainless hlau:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 thiab lwm yam. | |

| Cov kav dej hlau:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 thiab lwm yam. | |

| Nickel hlau:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 thiab lwm yam. | |

| Cr-Mo hlau:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, thiab lwm yam. | |

| Daim Ntawv Thov | Kev lag luam petrochemical; kev lag luam aviation thiab aerospace; kev lag luam tshuaj; cov pa roj tawm; fais fab nroj tsuag; kev tsim nkoj; kev kho dej, thiab lwm yam. |

| Cov txiaj ntsig | Npaj txhij Tshuag, lub sijhawm xa khoom sai dua; muaj nyob rau hauv txhua qhov ntau thiab tsawg, kho kom haum; zoo siab |

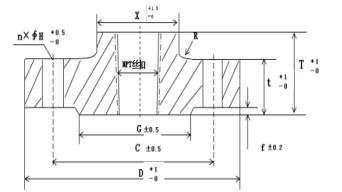

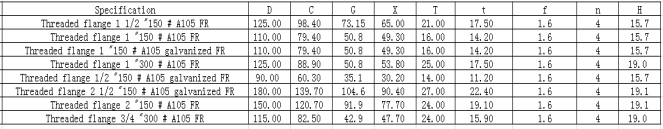

Cov Qauv Ntsuas

KHOOM TXHEEJ TXHEEM QHIA

1. Lub ntsej muag

Yuav tsum tsa lub ntsej muag (RF), lub ntsej muag tag nrho (FF), lub nplhaib sib koom ua ke (RTJ), Groove, Tongue, lossis kho kom haum.

2. Xov

NPT los yog BSP

3. CNC zoo tiav lawm

Kev ua tiav ntawm lub ntsej muag: Qhov ua tiav ntawm lub ntsej muag ntawm flange yog ntsuas raws li Arithmetical Average Roughness Height (AARH). Qhov ua tiav yog txiav txim siab los ntawm tus qauv siv. Piv txwv li, ANSI B16.5 qhia txog kev ua tiav ntawm lub ntsej muag hauv qhov ntau ntawm 125AARH-500AARH (3.2Ra txog 12.5Ra). Lwm cov kev ua tiav muaj nyob rau ntawm qhov kev thov, piv txwv li 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra lossis 6.3/12.5Ra. Qhov ntau ntawm 3.2/6.3Ra yog qhov feem ntau.

CIM THIAB NTIM KHOOM

• Txhua txheej siv yas zaj duab xis los tiv thaiv qhov chaw

• Rau txhua yam hlau tsis xeb, peb ntim los ntawm cov thawv plywood. Rau cov flange carbon loj dua, peb ntim los ntawm cov pallet plywood. Los yog peb ntim tau raws li koj xav tau.

• Lub cim xa khoom tuaj yeem ua tau raws li qhov kev thov

• Cov cim rau ntawm cov khoom tuaj yeem txiav los yog luam tawm. OEM raug txais.

KEV TSHAWB FAWB

• Kev xeem UT

• Kev xeem PT

• Kev xeem MT

• Kev ntsuas qhov ntev

Ua ntej xa khoom, peb pab neeg QC yuav npaj NDT kev xeem thiab kev tshuaj xyuas qhov ntev.Tsis tas li ntawd, txais TPI (kev tshuaj xyuas sab nraud).

TXHEEJ TXHEEM TXOG KEV UA HAUJ LWM

| 1. Xaiv cov khoom siv raw tiag tiag | 2. Txiav cov khoom siv raw | 3. Ua ntej cua sov |

| 4. Kev Ua Hlau | 5. Kev kho cua sov | 6. Kev Siv Tshuab Tsis Zoo |

| 7. Kev Tshawb Fawb | 8. Kev ua haujlwm zoo | 9. Kev cim |

| 10. Kev Tshuaj Xyuas | 11. Ntim Khoom | 12. Kev xa khoom |

COV NTAUB NTAWV KEV KOOM TES

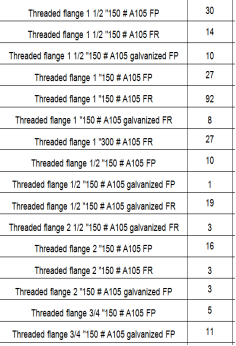

Qhov project no rau Brazil project. Qee yam khoom xav tau roj tiv thaiv xeb thiab qee yam khoom xav tau txheej galvanized.

Cov Lus Nug Feem Ntau

1. Dab tsi yog stainless hlau 304?

304 stainless hlau yog ib hom austenitic stainless hlau uas feem ntau siv nrog kev tiv taus corrosion zoo heev, lub zog siab thiab zoo formability. Nws yog dav siv hauv ntau yam lag luam vim nws qhov kev hloov pauv tau yooj yim thiab ruaj khov.

2. Dab tsi yog stainless hlau 304L?

Cov hlau tsis xeb 304L yog cov hlau tsis xeb uas muaj cov pa roj carbon tsawg dua li cov hlau tsis xeb 304. Nws muaj kev vuam zoo dua thaum tseem tswj tau qhov kev tiv thaiv xeb thiab cov khoom siv kho tshuab zoo sib xws. Qib no feem ntau yog siv rau hauv cov ntawv thov uas xav tau kev vuam.

3. Dab tsi yog stainless hlau 316?

316 stainless hlau yog ib hom hlau austenitic stainless hlau uas muaj molybdenum los txhim kho nws txoj kev tiv taus corrosion hauv marine thiab chloride ib puag ncig. Nws muaj lub zog zoo heev thiab kev tiv taus creep siab, ua rau nws haum rau ntau yam kev siv uas xav tau.

4. Dab tsi yog stainless hlau 316L?

316L stainless hlau yog cov pa roj carbon tsawg ntawm 316 stainless hlau. Nws tau txhim kho kev sib txuas thiab kev tiv thaiv rau intergranular corrosion. Qib no feem ntau siv rau hauv cov ntawv thov uas xav tau kev tiv thaiv corrosion siab thiab kev ua tau zoo heev.

5. Cov khoom siv yeeb nkab uas muaj xov forged yog dab tsi?

Cov khoom siv yeeb nkab uas muaj xov yog cov khoom siv yeeb nkab uas ua los ntawm kev ua kom cov hlau kub thiab siv lub zog kho tshuab los hloov nws mus rau hauv cov duab uas xav tau. Cov khoom siv no muaj xov nyob rau sab nraud thiab tuaj yeem txuas nrog cov yeeb nkab uas muaj xov kom yooj yim rau kev sib txuas kom muaj kev nyab xeeb thiab tsis muaj qhov xau.

6. Lub flange yog dab tsi?

Ib lub flange yog ib sab nraud lossis sab hauv uas siv los txhawb lossis txuas cov kav dej, cov li qub, lossis lwm yam khoom hauv lub kaw lus kav dej. Lawv muab ib txoj hauv kev yooj yim los sib sau ua ke, rhuav tshem thiab tswj lub kaw lus. Cov flanges hlau tsis xeb muaj kev tiv taus xeb zoo heev thiab tuaj yeem tiv taus qhov kub siab.

7. Cov qauv ASTM rau cov khoom siv sib txuas thiab cov flanges yog dab tsi?

Cov qauv ASTM yog cov qauv uas tau lees paub thoob ntiaj teb uas tau tsim los ntawm American Society for Testing and Materials. Cov qauv no ua kom ntseeg tau tias cov khoom siv forged threaded thiab flanges ua tau raws li cov kev cai tshwj xeeb rau cov khoom siv sib xyaw, qhov loj me, cov khoom siv kho tshuab thiab cov txheej txheem kuaj.

8. Cov txiaj ntsig ntawm kev siv cov yeeb nkab fittings thiab flanges uas ua los ntawm cov hlau tsis xeb yog dab tsi?

Cov yeeb nkab fittings thiab flanges uas ua los ntawm cov hlau tsis xeb muaj ntau yam zoo, suav nrog kev tiv taus xeb zoo heev, muaj zog heev, ruaj khov thiab siv tau ntau yam. Lawv tuaj yeem tiv taus qhov kub thiab txias heev, kev nyuaj siab thiab ib puag ncig hnyav, ua rau lawv haum rau ntau yam kev siv.

9. Hauv cov teb twg uas cov yeeb nkab fittings thiab flanges uas ua los ntawm cov hlau tsis xeb forged feem ntau siv?

Cov fittings thiab flanges no siv dav hauv kev lag luam xws li roj thiab roj av, petrochemical, tshuaj lom neeg, kev tsim hluav taws xob, tshuaj, pulp thiab ntawv, kev ua zaub mov thiab kev kho dej. Lawv feem ntau siv rau hauv cov kav dej, cov kav dej, cov chaw ua roj thiab lwm yam kev siv uas xav tau kev sib txuas zoo thiab kev ua haujlwm zoo.

10. Yuav ua li cas xaiv cov hlau tsis xeb uas tsim nyog forged threaded yeeb nkab fittings thiab flanges?

Yuav kom xaiv tau cov fittings thiab flanges kom raug, xav txog tej yam xws li qhov yuav tsum tau siv, tej yam kev ua haujlwm (kub, siab, thiab tej yam corrosive), qhov loj ntawm cov yeeb nkab, thiab kev sib haum nrog cov kua dej uas raug thauj mus los. Nws raug pom zoo kom sab laj nrog tus neeg muag khoom lossis tus engineer uas muaj kev paub dhau los kom tau txais kev qhia txog kev xaiv cov fittings thiab flanges kom haum rau koj cov kev xav tau tshwj xeeb.

Cov khoom siv yeeb nkab yog cov khoom tseem ceeb hauv lub kaw lus yeeb nkab, siv rau kev sib txuas, kev hloov pauv, kev hloov pauv, kev hloov qhov loj me, kev kaw lossis kev tswj cov dej ntws. Lawv siv dav hauv cov teb xws li kev tsim kho, kev lag luam, lub zog thiab cov kev pabcuam hauv nroog.

Cov Haujlwm Tseem Ceeb:Nws tuaj yeem ua haujlwm xws li txuas cov kav dej, hloov kev ntws, faib thiab sib koom ua ke, kho cov kav dej txoj kab uas hla, kaw cov kav dej, tswj thiab tswj hwm.

Daim Ntawv Thov Scope:

- Kev muab dej thiab dej ntws hauv tsev:Cov luj tshib PVC thiab PPR tris yog siv rau cov kav dej hauv av.

- Cov kav dej lag luam:Cov flanges hlau tsis xeb thiab cov hlau sib xyaw ua ke yog siv los thauj cov tshuaj lom neeg.

- Kev thauj mus los ntawm lub zog:Cov yeeb nkab hlau siab siv rau hauv cov kav dej roj thiab roj av.

- HVAC (Kev Ua Kub, Kev Pa, thiab Kev Txias):Cov yeeb nkab tooj liab yog siv los txuas cov kav dej txias, thiab cov pob qij txha uas yoog tau yog siv rau kev txo kev co.

- Kev ywg dej rau kev ua liaj ua teb:Cov khoom sib txuas sai ua rau kev sib dhos thiab kev rhuav tshem ntawm cov tshuab txau dej.

-

Qhov (Socket) vuam flange A105 carbon steel SW RTJ 3/4...

-

ASTM A182 F51 F53 BL ANSI B16.5 Cov hlau tsis xeb...

-

Hlau Stainless 304 304L 316 316L ASTM forged t...

-

ANSI B16.5 Forged Stainless Steel Socket Weld Fittings

-

ANSI DIN Forged Class150 Stainless Hlau Slip o...

-

Kev Kho Kom Haum Flange ANSI / ASME / JIS Txheem Carbon...