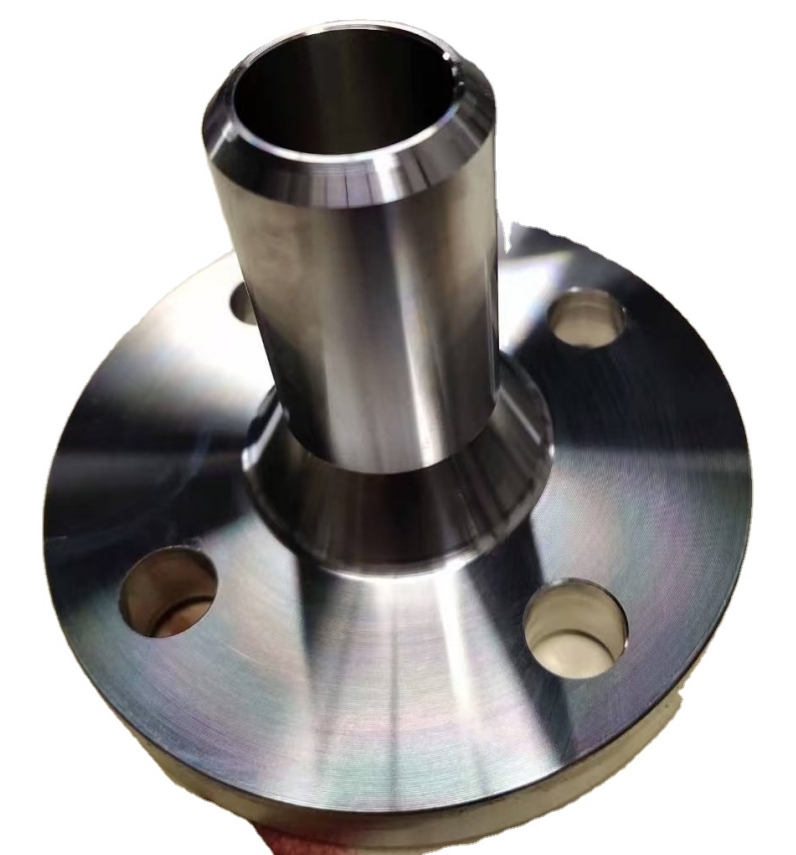

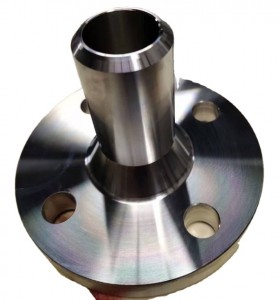

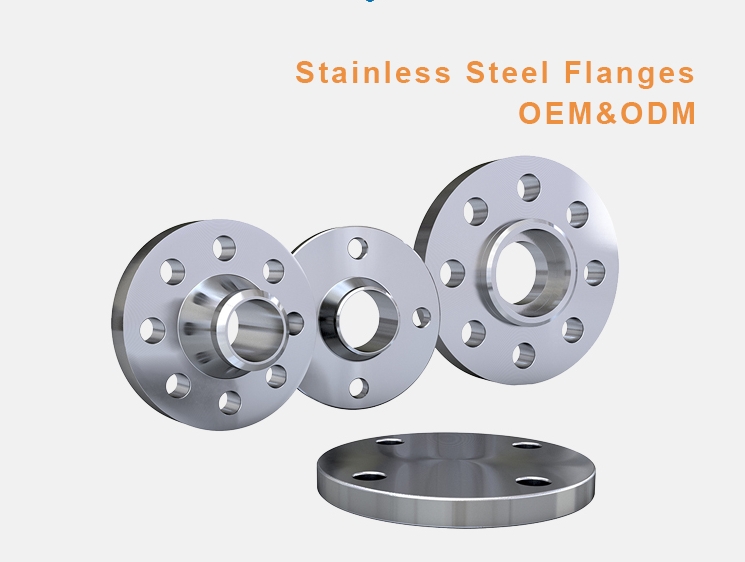

Kev Kho Kom Zoo Nkauj Ntev Weld Caj Dab (LWN) Flange

Peb Cov Flanges Ntev Weld Neck (LWN) uas Tau Kho Kom Haum Rau Cov Kav Dej Tseem Ceeb yog qhov kev daws teeb meem zoo tshaj plaws rau cov kav dej tseem ceeb uas cov flanges txheem tsis tuaj yeem ua tau raws li cov kev xav tau tshwj xeeb ntawm cov haujlwm. Tsim los rau cov xwm txheej kev pabcuam hnyav hauv kev lag luam offshore, petrochemical, kev tsim hluav taws xob, thiab kev lag luam ua haujlwm siab, cov flanges no tau tsim los rau cov kev xav tau ua haujlwm tshwj xeeb los ntawm kev tsim kho siab heev thiab kev tsim khoom raug.

Tsis zoo li cov khoom siv uas twb muaj lawm, txhua lub flange LWN uas tau kho kom haum raws li qhov xav tau raug tshuaj xyuas kom zoo kom ntseeg tau tias muaj kev ua haujlwm zoo tshaj plaws hauv qab qhov siab, kub, xeb, thiab kev ntxhov siab ntawm lub tshuab. Lub caj dab ntev tsim muab kev faib tawm kev ntxhov siab zoo dua, ua rau cov flanges no tshwj xeeb tshaj yog rau cov hlab ntsha siab, cov khoom hloov pauv cua sov, cov reactors, thiab cov kav dej tseem ceeb uas qhov kev tiv taus qaug zog thiab kev ntseeg siab mus sij hawm ntev yog qhov tseem ceeb. Peb lub peev xwm hloov kho tau hloov cov lus qhia flange txheem mus rau hauv cov kev daws teeb meem uas tau tsim los rau cov kev siv lag luam nyuaj tshaj plaws.

Kev Tswj Xyuas Zoo Rau Cov Cheebtsam Tshwj Xeeb:

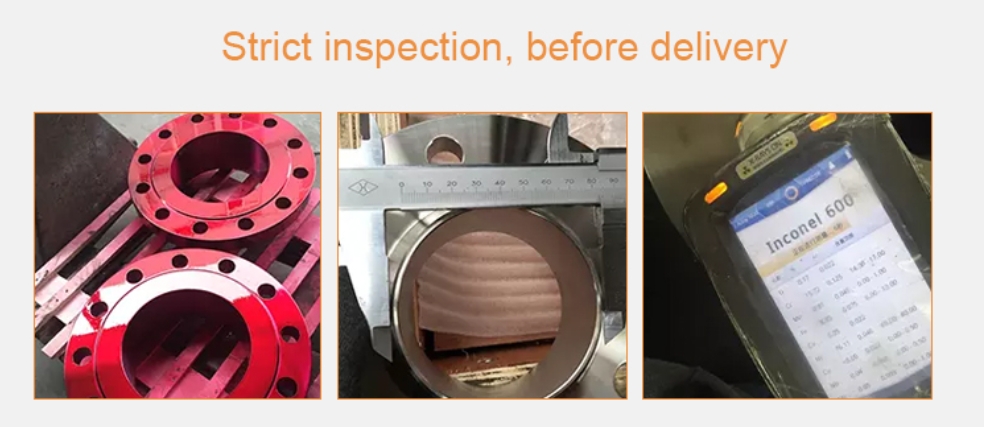

Kev Txheeb Xyuas Tus Qauv Tsim: Kev txheeb xyuas tus qauv tsim sab nraud rau cov ntawv thov tseem ceeb

Kev Ntsuas Prototype: Kev Tsim Cov Khoom Siv Rau Kev Txheeb Xyuas Cov Khoom Siv Thiab Cov Txheej Txheem

NDT Qib Siab: Phased array UT, TOFD, thiab digital radiography rau cov geometries nyuaj

Kev Txheeb Xyuas Qhov Ntev: Kev luam theej duab laser thiab kev ntsuas 3D rau cov profiles tshwj xeeb

KHOOM TXHEEJ TXHEEM QHIA

Kev Muaj Peev Xwm Tsim Khoom Siab Tshaj Plaws:

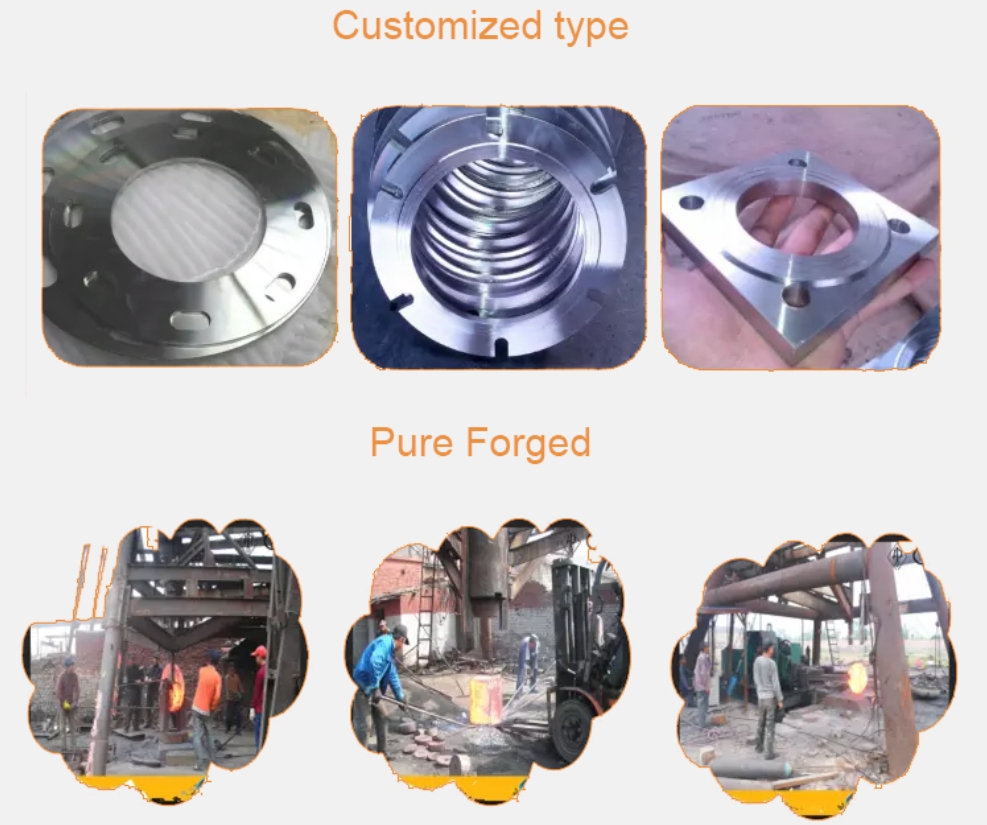

Kev Forging: Kaw-die forging rau cov qauv noob zoo dua hauv cov ntawv thov siab

Kev Tsim Phaj: Rau cov flanges loj heev uas kev forging tsis yooj yim sua

Kev Txheej Txheem/Kev Txheej Txheem: Kev sib txuas ntawm cov hlau tsis xeb rau ntawm cov hlau carbon

Kev Ua Haujlwm Zoo: 5-axis CNC machining rau cov geometries nyuaj

Kev Kho Mob Kub: Kev hloov kho cua sov (normalizing, quenching, tempering) raws li cov khoom siv xav tau

CIM THIAB NTIM KHOOM

Hnyav-Duty Crating: Engineered ntoo crates nrog kev cai sab hauv bracing

Kev Tiv Thaiv Kev Xeb: VCI txheej, cov tshuab desiccant, thiab cov ntim khoom tswj huab cua

Kev Tiv Thaiv Nto: Kev npog tshwj xeeb rau cov nto machined thiab cov qhov threaded

Cov Kev Cai Tswjfwm: Kev sib xyaw ua ke ntawm cov lugs nqa thiab qhov chaw nruab nrab ntawm lub ntiajteb txawj nqus

KEV TSHAWB FAWB

Kev Ntsuas Kev Tsim Qauv:

Kev Tshuaj Xyuas Kev Nyuaj Siab FEA: ANSYS lossis kev lees paub software sib npaug

Kev Ntsuas Siab ntawm Qauv Qauv: Kev sim hydrostatic/pneumatic ntawm cov khoom qauv

Kev Ntsuas Kev Sib Xws ntawm Cov Khoom Siv: Kev ntsuas kev xeb hauv cov chaw ua haujlwm simulated

Kev Tshuaj Xyuas Kev Qaug Zog: Kev sim ua kom muaj kev thauj khoom mus los rau cov xwm txheej kev pabcuam dynamic

TXHEEJ TXHEEM TXOG KEV UA HAUJ LWM

| 1. Xaiv cov khoom siv raw tiag tiag | 2. Txiav cov khoom siv raw | 3. Ua ntej cua sov |

| 4. Kev Ua Hlau | 5. Kev kho cua sov | 6. Kev Siv Tshuab Tsis Zoo |

| 7. Kev Tshawb Fawb | 8. Kev ua haujlwm zoo | 9. Kev cim |

| 10. Kev Tshuaj Xyuas | 11. Ntim Khoom | 12. Kev xa khoom |

Daim Ntawv Thov

Offshore & Subsea: Kev sib txuas Manifold, Christmas tsob ntoo flanges, riser kev sib txuas

Kev Tsim Hluav Taws Xob: Cov flanges ntawm lub cev nuclear, cov tshuab turbine bypass

Petrochemical: Cov flanges reactor siab, kev sib txuas ntawm lub cub tawg reformer

Kev Pabcuam Cryogenic: LNG liquefaction thiab regasification chaw

Kev Khawb Av & Cov Khoom Siv Minerals: Cov tshuab autoclave siab thiab digester

Peb qhov kev pabcuam LWN flange uas tau kho tshwj xeeb sawv cev rau ntau tshaj li kev tsim khoom xwb - nws yog ib txoj hauv kev koom tes los daws cov teeb meem kev tsim kho vaj tse nyuaj. Peb ua haujlwm nrog koj cov pab pawg engineering los tsim cov kev daws teeb meem uas tsis yog tsuas yog ua tau raws li cov lus qhia xwb tab sis kuj ua kom zoo dua qub, txo cov nqi siv tas mus li, thiab xyuas kom muaj kev ntseeg siab mus sij hawm ntev hauv kev siv hauv kev lag luam uas xav tau ntau tshaj plaws hauv ntiaj teb.

Q: Koj puas txais tau TPI?

A: Yog, paub tseeb. Txais tos tuaj xyuas peb lub Hoobkas thiab tuaj ntawm no los tshuaj xyuas cov khoom thiab tshuaj xyuas cov txheej txheem ntau lawm.

Q: Koj puas muab tau daim ntawv e, Daim ntawv pov thawj keeb kwm?

A: Yog, peb tuaj yeem muab khoom.

Q: Koj puas tuaj yeem muab daim ntawv qhia nqi thiab CO nrog lub koom haum lag luam?

A: Yog, peb tuaj yeem muab khoom.

Q: Koj puas txais tau L/C ncua sijhawm 30, 60, 90 hnub?

A: Peb ua tau. Thov sib tham nrog kev muag khoom.

Q: Koj puas txais tau O/A them nyiaj?

A: Peb ua tau. Thov sib tham nrog kev muag khoom.

Q: Koj puas muab tau cov qauv?

A: Yog, qee cov qauv yog pub dawb, thov nrog cov neeg muag khoom tham.

Q: Koj puas tuaj yeem muab cov khoom uas ua raws li NACE?

A: Yog, peb ua tau.

Cov khoom siv yeeb nkab yog cov khoom tseem ceeb hauv lub kaw lus yeeb nkab, siv rau kev sib txuas, kev hloov pauv, kev hloov pauv, kev hloov qhov loj me, kev kaw lossis kev tswj cov dej ntws. Lawv siv dav hauv cov teb xws li kev tsim kho, kev lag luam, lub zog thiab cov kev pabcuam hauv nroog.

Cov Haujlwm Tseem Ceeb:Nws tuaj yeem ua haujlwm xws li txuas cov kav dej, hloov kev ntws, faib thiab sib koom ua ke, kho cov kav dej txoj kab uas hla, kaw cov kav dej, tswj thiab tswj hwm.

Daim Ntawv Thov Scope:

- Kev muab dej thiab dej ntws hauv tsev:Cov luj tshib PVC thiab PPR tris yog siv rau cov kav dej hauv av.

- Cov kav dej lag luam:Cov flanges hlau tsis xeb thiab cov hlau sib xyaw ua ke yog siv los thauj cov tshuaj lom neeg.

- Kev thauj mus los ntawm lub zog:Cov yeeb nkab hlau siab siv rau hauv cov kav dej roj thiab roj av.

- HVAC (Kev Ua Kub, Kev Pa, thiab Kev Txias):Cov yeeb nkab tooj liab yog siv los txuas cov kav dej txias, thiab cov pob qij txha uas yoog tau yog siv rau kev txo kev co.

- Kev ywg dej rau kev ua liaj ua teb:Cov khoom sib txuas sai ua rau kev sib dhos thiab kev rhuav tshem ntawm cov tshuab txau dej.