Cov Hlau Carbon Low-Kub Seamless Lub Luj Tshib

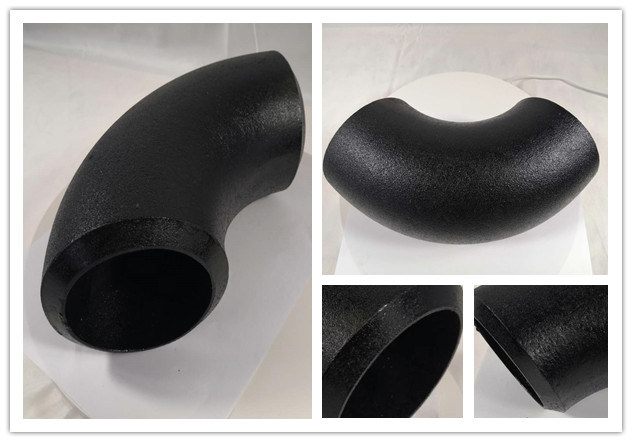

Tsim los rau kev pabcuam tseem ceeb hauv qhov chaw cryogenic thiab qis-kub, peb cov Carbon Steel Low-Temperature Seamless Elbows yog tsim los ntawm cov ntaub ntawv zoo xws li API 5L X65 lossis tshwj xeeb ASTM A333 Qib 6 steel. Muaj nyob rau hauv ob qho tib si 90 ° thiab 180 ° configurations nrog tus qauv 1.5D Long Radius, cov butt weld elbows no yog tsim los tswj hwm qhov tshwj xeeb toughness thiab kev ncaj ncees ntawm cov qauv nyob rau hauv qhov kub qis heev, tiv thaiv brittle fracture hauv daim ntawv thov xws li LNG ua, cryogenic cia, thiab arctic pipeline systems.

Ua los ntawm kev tsim cov txheej txheem kub tsis muaj qhov tsis zoo, cov luj tshib no muaj kev sib txuas zoo dua thiab kev ruaj khov ntawm lub siab piv rau cov khoom sib txuas. Lub vojvoog khoov 1.5D ua kom muaj kev ntws du nrog qhov tsawg kawg nkaus ntawm kev co thiab kev poob siab, thaum kev npaj vuam bevel kom raug lav qhov zoo, kev sib txuas tag nrho. Cov khoom no yog qhov kev xaiv txhim khu kev qha rau cov engineers tsim cov kav dej ruaj ntseg thiab ruaj khov uas yuav tsum ua haujlwm tau zoo los ntawm qhov kub thiab txias mus rau qhov kub thiab txias.

COV KHOOM TXHEEJ TXHEEM

| Lub Npe Khoom | Lub luj tshib yeeb nkab |

| Loj | 1/2 "-36" lub luj tshib tsis muaj qhov sib txuas (SMLS lub luj tshib), 26 "-110" vuam nrog seam. Qhov loj tshaj plaws sab nraud tuaj yeem yog 4000mm |

| Tus Qauv | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, thiab lwm yam. |

| Phab ntsa tuab | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS thiab lwm yam. |

| Qib kawm | 30° 45° 60° 90° 180°, thiab lwm yam |

| Lub vojvoog | LR/lub vojvoog ntev/R=1.5D, SR/lub vojvoog luv/R=1D |

| Xaus | Bevel kawg / BE / buttweld |

| Nto | xim xwm, varnished, dub painting, anti-xeb roj thiab lwm yam. |

| Khoom siv | Cov hlau carbon:A234WPB, A420 WPL6 St37, St45, E24, A42CP, 16Mn, Q345, P245GH, P235GH, P265GH, P280GH, P295GH, P355GH thiab lwm yam. |

| Cov kav dej hlau:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 thiab lwm yam. | |

| Cr-Mo hlau hlau:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, thiab lwm yam. | |

| Daim Ntawv Thov | Kev lag luam petrochemical; kev lag luam aviation thiab aerospace; kev lag luam tshuaj, cov pa roj tawm; fais fab nroj tsuag; nkoj tsim; kev kho dej, thiab lwm yam. |

| Cov txiaj ntsig | Npaj txhij Tshuag, lub sijhawm xa khoom sai dua; muaj nyob rau hauv txhua qhov ntau thiab tsawg, kho kom haum; zoo siab |

COV YEEB NKAB

Cov khoom siv yeeb nkab vuam taub qab suav nrog lub luj tshib yeeb nkab hlau, lub tee yeeb nkab hlau, lub reducer yeeb nkab hlau, lub hau yeeb nkab hlau. Tag nrho cov khoom siv yeeb nkab vuam taub qab no, peb tuaj yeem muab ua ke, peb muaj ntau tshaj 20 xyoo kev paub txog kev tsim khoom.

Yog tias koj tseem xav paub ntxiv txog lwm yam khoom siv, thov nias qhov LINK kom paub meej ntxiv.

YEEB YAJ KHO YEEB YAJ KOM TXO Lub hau yeeb nkab YEEB YAJ KHOOV COV KHOOM SIV FORGED

BUTT WELDED YEEB YAJ KUB

Lub luj tshib hlau yog ib qho tseem ceeb hauv lub kaw lus kav dej rau kev hloov pauv cov kua dej ntws. Nws yog siv los txuas ob lub kav dej uas muaj tib lub npe lossis sib txawv, thiab ua kom lub kav dej tig mus rau ib qho kev taw qhia ntawm 45 degree lossis 90 degree.

Rau cov yeeb nkab lag luam lub luj tshib, hom txuas kawg yog butt weld, raws li ANSI B16.25. Butt welded tuaj yeem piav qhia butt welding, buttweld, bevel end. BW

HOM LUB LUAG HAUJ LWM

Lub luj tshib yuav tsum muaj txij li lub kaum sab xis, hom kev sib txuas, qhov ntev thiab lub vojvoog, hom khoom siv.

Faib tawm los ntawm Lub kaum sab xis

Raws li peb paub, raws li cov kua dej ntawm cov kav dej, lub luj tshib tuaj yeem muab faib ua ntau qib sib txawv, xws li 45 degree, 90 degree, 180 degree, uas yog cov degrees feem ntau. Kuj tseem muaj 60 degree thiab 120 degree, rau qee cov kav dej tshwj xeeb.

Rau 90 degree luj tshib, kuj piav qhia 90d luj tshib, lossis 90 degree luj tshib.

Lub Luj Tshib Radius yog dab tsi

Lub luj tshib radius txhais tau tias lub vojvoog nkhaus. Yog tias lub vojvoog zoo ib yam li txoj kab uas hla ntawm cov yeeb nkab, nws hu ua lub luj tshib luv radius, tseem hu ua SR luj tshib, feem ntau rau cov kav dej siab qis thiab cov kav dej ceev qis.

Yog tias lub vojvoog loj dua li lub yeeb nkab txoj kab uas hla, R ≥ 1.5 Txoj kab uas hla, ces peb hu nws tias lub luj tshib ntev (LR Lub Luj Tshib), siv rau cov kav dej siab thiab cov kav dej ntws siab.

Yog tias lub vojvoog ntau dua 1.5D, ib txwm hu ua khoov. lub luj tshib khoov cov yeeb nkab fittings. Xws li 2d luj tshib, 2d khoov, 3d luj tshib, 3d khoov, thiab lwm yam.

Kev faib tawm los ntawm cov khoom siv

Cov hlau carbon, tseem hu ua cov hlau tsis muaj zog lossis cov hlau dub. Xws li ASTM A234 WPB

Yog koj xav tau cov stainless steel elbows, thov nias qhov link no kom paub ntxiv:Cov Hlau Stainless Hlau

Hom duab

Yuav ua tau lub luj tshib sib npaug los yog txo lub luj tshib

Nto ntawm lub luj tshib

Kev Tawm Tsam Xuab Zeb

Tom qab ua kom kub, peb npaj cov xuab zeb kom ua rau qhov chaw huv thiab du.

Tom qab xuab zeb tawg, kom tsis txhob xeb, yuav tsum pleev xim dub lossis roj tiv thaiv xeb, Kub dip galvanized (HDG), epoxy, 3PE, qhov chaw ploj mus, thiab lwm yam. Qhov ntawd nyob ntawm tus neeg siv khoom thov.

Khoom siv & Metallurgy:

Cov kav dej no yog ua los ntawm cov yeeb nkab uas tsis muaj qhov sib txuas thiab tau ntawv pov thawj raws li API 5L X65 rau kev siv zog siab lossis ASTM A333 Qib 6 rau kev tiv thaiv qhov kub thiab txias qis. Cov hlau no yog cov hlau zoo, raug tua tag nrho, thiab feem ntau ua kom zoo li qub kom ua tiav cov nqi zog cuam tshuam Charpy V-Notch (CVN) ntawm qhov kub tsawg kawg nkaus uas tau teev tseg. Cov tshuaj lom neeg raug tswj kom txwv cov ntsiab lus uas ua rau brittleness, ua kom ntseeg tau tias muaj kev tawg zoo heev hauv huab cua txias.

Cov Txheej Txheem Tsim Khoom Tsis Muaj Qhov Txuas:

Cov luj tshib yog tsim los ntawm kev siv kev tswj hwm kub induction khoov ntawm cov yeeb nkab seamless lossis cov txheej txheem kub thawb. Ob txoj kev khaws cia cov khoom siv homogeneous yam tsis tsim cov kab sib txuas ntev. Tom qab tsim, cov luj tshib raug kho cua sov kom zoo dua qub kom txhim kho cov qauv noob, txo kev ntxhov siab, thiab rov qab kho cov khoom siv kho tshuab tseem ceeb rau kev ua haujlwm kub qis.

Kev Tsim Kho Kom Zoo & Qhov Loj:

Tsim tawm raws li ASME B16.9 kev kam rau siab.

Qhov Loj Ntawm Nruab Nrab Mus Rau Qhov Kawg / Nruab Nrab Mus Rau Nruab Nrab: Tswj tau kom raug rau qhov kev teeb tsa kav dej kom raug.

Kev Tswj Qhov Thickness ntawm Phab Ntsa: Cov txheej txheem no ua kom cov phab ntsa tuab sib npaug. Kev saib xyuas tshwj xeeb yog muab rau qhov extrados (sab nraud khoov) kom ua kom nyias nyias hauv ASME B16.9 cov kev txwv uas tso cai (feem ntau yog siab tshaj 12.5%).

Kev Tawm Ntawm Qhov Puag Ncig & Bevel: Cov kawg yog machined kom ntseeg tau tias qhov puag ncig rau kev haum zoo meej. Ib qho sib xws 37.5 ° vuam bevel nrog 1.6mm av tau npaj rau ob qho kawg.

Kev Cim & Kev Taug Qab Tau:

Txhua lub luj tshib raug ntaus cim tas mus li raws li ASTM A960, suav nrog: Cov Khoom Siv (piv txwv li, API 5L X65 lossis A333 Gr.6), Tus lej cua sov, Qhov loj me, Daim ntawv teev sijhawm ntawm phab ntsa, ID ntawm Chaw Tsim Khoom, thiab tus cim "LT" (Kub qis). Qhov no ua kom ntseeg tau tias muaj kev taug qab tag nrho los ntawm lub tshuab hlau mus rau cov khoom tiav.

KEV KHO KUB

1. Khaws cov qauv raw khoom kom taug qab.

2. Npaj kev kho cua sov raws li tus qauv nruj me ntsis.

CIM

Ntau yam kev cim ua haujlwm, tuaj yeem nkhaus, pleev xim, sau npe. Los yog raws li koj qhov kev thov. Peb lees txais cim koj lub LOGO.

COV DUAB TXHAIS LUS

1. Qhov kawg bevel raws li ANSI B16.25.

2. Xuab zeb ua ntej, tom qab ntawd pleev xim zoo meej. Kuj tseem tuaj yeem pleev xim.

3. Tsis muaj lamination thiab tawg.

4. Tsis muaj kev kho weld.

KEV TSHAWB FAWB

Txhua lub cua sov ntawm cov hlau tau muab nrog Daim Ntawv Pov Thawj Xeem Mill (MTC 3.2) tag nrho cov lus qhia txog chemistry thiab cov khoom siv kho tshuab. Peb ua qhov Kev Txheeb Xyuas Khoom Siv Zoo (PMI) thiab kev kuaj xyuas tuab ultrasonic ntawm cov yeeb nkab nyoos. Qhov kev txheeb xyuas tseem ceeb yog Charpy V-Notch Impact Testing ib ASTM A370. Cov txheej txheem ntawm peb cov qauv raug kuaj ntawm qhov kub tsim tsawg kawg nkaus (piv txwv li, -46 ° C) kom ntseeg tau tias lub zog nqus tau ua tau raws li lossis tshaj qhov yuav tsum tau ua (piv txwv li, ≥ 20J lossis 27J nruab nrab ib ASTM A333).

NTIM & XA KHOOM

Txhawm rau tiv thaiv kev xeb thaum lub sijhawm thauj mus los, cov qhov kawg beveled thiab cov chaw uas raug nthuav tawm raug coated nrog ib ntus, yooj yim tshem tawm xeb tiv thaiv. Txhua lub luj tshib ces raug qhwv hauv VCI (Vapor Corrosion Inhibitor) zaj duab xis lossis cov yas hnyav. Rau cov luj tshib hnyav lossis loj-txoj kab uas hla, cov ntoo cradles lossis cov thawv tshwj xeeb raug siv los muab kev txhawb nqa thiab tiv thaiv kev hloov pauv.

Peb siv ntau hom kev xa khoom raws li qhov loj thiab qhov ceev: kev thauj khoom los ntawm huab cua rau cov khoom tseem ceeb uas yuav tsum tau xa sai, lub thawv ntim khoom hauv hiav txwv (FCL/LCL) rau cov khoom ntau, thiab lub thawv ntim tiaj tiaj rau cov khoom loj. Txhua daim ntawv xa khoom (Daim Ntawv Teev Khoom, Daim Ntawv Qhia Txog Kev Lag Luam, Daim Ntawv Pov Thawj Keeb Kwm, thiab Pob Khoom Xeem Tag Nrho) tau npaj los pab txhawb kev tshem tawm kev lis kev cai rau cov haujlwm lag luam thoob ntiaj teb.

Daim Ntawv Thov

Roj thiab Roj Av (Arctic thiab Offshore):

Cov kav dej hauv qab dej hiav txwv, cov chaw tsim khoom hauv hiav txwv hauv thaj chaw txias, thiab cov txheej txheem sib sau ua ke hauv hiav txwv hauv cov huab cua arctic.

Kev Lag Luam LNG (Cov Roj Av Uas Ua Los Ntawm Cov Kua):

Cov thawv txias, cov kab ua kua dej, cov kab hloov LNG, thiab cov kav dej cia khoom ua haujlwm ntawm qhov kub cryogenic.

Kev Ua Haujlwm Cryogenic:

Cov chaw tsim roj av rau kev lag luam (O2, N2, Ar sib cais), cov chaw tsim ethylene, thiab cov kav dej thauj CO2.

Lub zog & Tshuaj lom neeg:

Cov kab ua haujlwm hauv cov chaw nyob hauv qhov chaw txias heev.

Kev Tshwj Xeeb hauv Cov Khoom Siv Kub Qis:

Peb muaj kev txawj ntse tob hauv cov lus qhia tshwj xeeb, kev sim, thiab kev tuav cov hlau carbon uas kub tsawg, kom ntseeg tau tias cov khoom xa tuaj yeem lav qhov ua tau zoo.

Kev Tsim Khoom Uas Tsis Muaj Qhov Txuas:

Peb txoj kev cog lus rau kev tsim khoom tsis muaj teeb meem lav qhov kev ncaj ncees siab tshaj plaws rau kev pabcuam cryogenic tseem ceeb qhov twg qhov tsis zoo ntawm weld tsis tuaj yeem lees txais.

Pob Ntawv Pov Thawj Ua Ke:

Peb muab cov ntaub ntawv pov thawj zoo tshaj plaws hauv kev lag luam, tshwj xeeb tshaj yog cov ntawv pov thawj Charpy Impact Test Reports, uas yog qhov tseem ceeb rau kev pom zoo engineering thiab kev tshuaj xyuas kev nyab xeeb hauv cov haujlwm qis-kub.

Kev Kho Kom Haum Rau Qhov Project:

Peb tsim cov khoom raws li qhov xav tau tshwj xeeb ntawm cov haujlwm, suav nrog qhov loj me tshwj xeeb, qhov kub thiab txias ntawm kev sim cuam tshuam, thiab NDT ntxiv, pabcuam EPC cov neeg cog lus thiab cov neeg siv kawg ncaj qha.

Kev Thauj Mus Los Thoob Ntiaj Teb rau Cov Kev Tsim Kho Tseem Ceeb: Peb yog cov neeg koom tes uas muaj kev paub dhau los hauv cov haujlwm tseem ceeb ntawm lub zog, ua kom ntseeg tau tias cov khoom tshwj xeeb, tau ntawv pov thawj no raug xa mus raws sijhawm mus rau thaj chaw deb lossis qhov chaw xav tau ntau, txhawb nqa los ntawm kev taug qab tag nrho thiab cov ntaub ntawv zoo.

Cov khoom siv yeeb nkab yog cov khoom tseem ceeb hauv lub kaw lus yeeb nkab, siv rau kev sib txuas, kev hloov pauv, kev hloov pauv, kev hloov qhov loj me, kev kaw lossis kev tswj cov kua dej ntws. Lawv siv dav hauv cov teb xws li kev tsim kho, kev lag luam, lub zog thiab cov kev pabcuam hauv nroog.

Cov Haujlwm Tseem Ceeb:Nws tuaj yeem ua haujlwm xws li txuas cov kav dej, hloov kev ntws, faib thiab sib koom ua ke, kho cov kav dej txoj kab uas hla, kaw cov kav dej, tswj thiab tswj hwm.

Daim Ntawv Thov Scope:

- Kev muab dej thiab dej ntws hauv tsev:Cov luj tshib PVC thiab PPR tris yog siv rau cov kav dej hauv av.

- Cov kav dej lag luam:Cov flanges hlau tsis xeb thiab cov hlau sib xyaw ua ke yog siv los thauj cov tshuaj lom neeg.

- Kev thauj mus los ntawm lub zog:Cov yeeb nkab hlau siab siv rau hauv cov kav dej roj thiab roj av.

- HVAC (Kev Ua Kub, Kev Pa, thiab Kev Txias):Cov yeeb nkab tooj liab yog siv los txuas cov kav dej txias, thiab cov pob qij txha uas yoog tau yog siv rau kev txo kev co.

- Kev ywg dej rau kev ua liaj ua teb:Cov khoom sib txuas sai ua rau kev sib dhos thiab kev rhuav tshem ntawm cov tshuab txau dej.

-

ANSI b16.9 36 nti teem sijhawm 40 Butt Weld carbon...

-

Asme b16.9 teem sijhawm 80 cov yeeb nkab hlau tee ...

-

Cov hlau carbon 45 degree khoov 3d bw 12.7mm WT AP...

-

SUS304 316 yeeb nkab fittings Stainless hlau luj tshib ...

-

ANSI B16.9 Cov Hlau Carbon 45 Degree Vuam Khoov

-

ANSI B16.9 taub qab vuam yeeb nkab haum carbon hlau ...